If you have any questions about the product, please feel free to contact us. In addition to the products listed here, we also carry a large number of Molding Machines.

Technical Information

01.

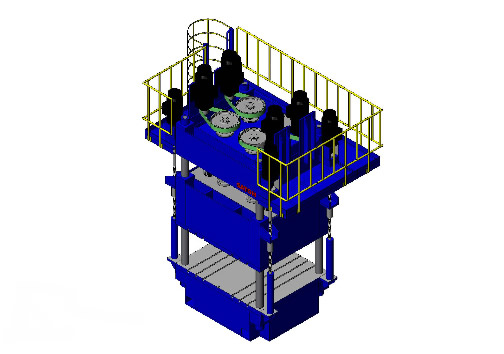

Features of SATOH Vertical Press

We manufacture presses that meet the needs of our customers.

Product Information

02.

Electric servo direct pressure press

To high-speed, high-precision injection compression molding by electrification

Product Information

03.

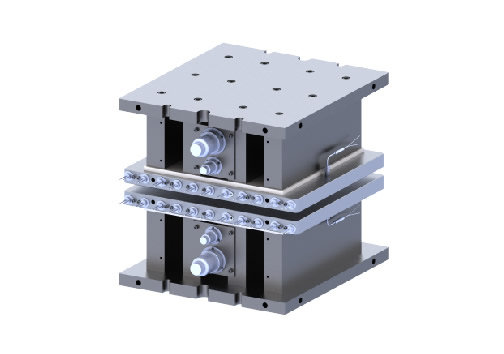

Low height Press

Achieved compactness with an electric serve press

Technical Information

04.

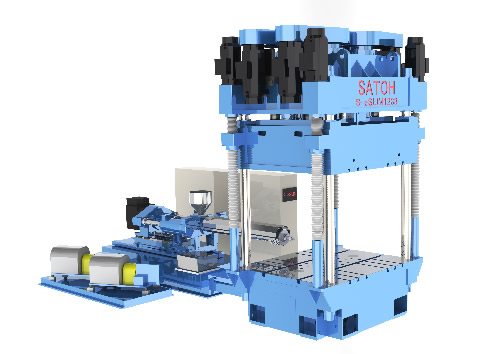

Injection Compression Molding Machine (SLIM)

This is an effective process for large molded products and synthetic products with skin.

Product Information

05.

Injection compression molding machine for ultra-large products

t is possible to mold large products that exceed the limit of injection.

Product Information

06.

Injection compression molding machine for ultra-large products (S-eSLIM)

Ideal for thin-wall molding and synthetic molding with skin material

Product Information

07.

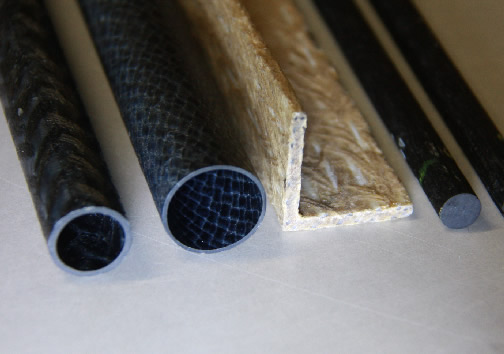

C (G) FRTP hybrid molding machine

We accept all peripheral systems such as base material transportation and heating.

Photo: Provided by Takagi Seiko

Technical Information

08.

Hybrid molding adopted for bumper beam

Adopted for Honda vehicles by Takagi Seiko Co., Ltd. technology

Photo: Provided by Takagi Seiko

Technical Information

09.

Advantages of C (G) FRTP hybrid molding

One-step molding of complex shaped products is possible

Technical Information

10.

C (G) FRTP base material heating / transfer system

We propose an automated optimum system together with a molding machine.

Product Information

11.

C (G) FRTP molding basic research laboratory machine

It can also be used for mass production of small products.

Product Information

12.

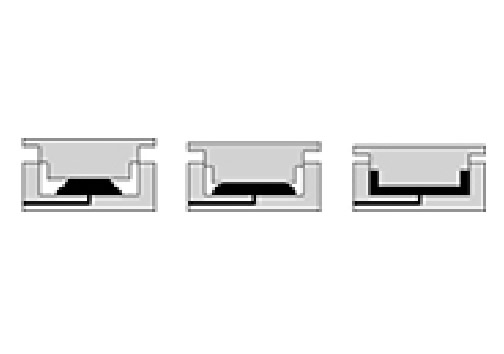

Back molding

Expanding the use of seat materials by adding ribs and clip seats

Peripherals

13.

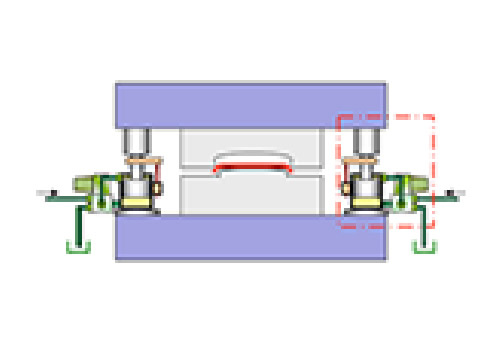

Press parallel control device

Improves wall thickness variation of molded products

Peripherals

14.

Foam molding device (REAC)

High-precision core back with small variation in wall thickness of molded products

Product Information

15.

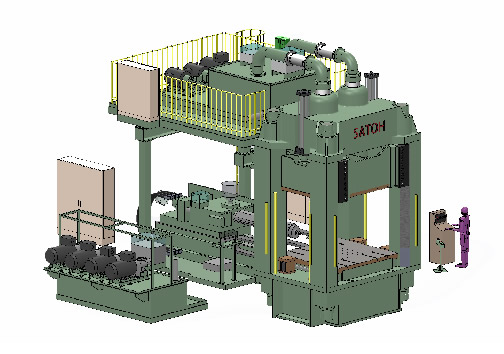

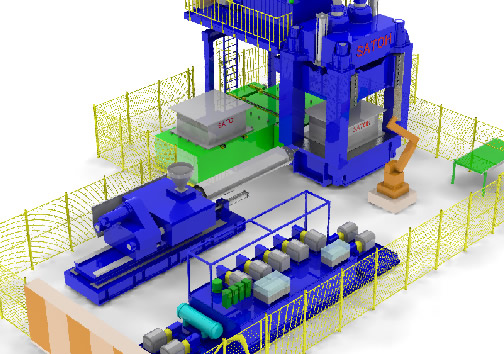

Sheet stamping molding equipment

We accept all systems such as base material transfer and heating equipment.

Product Information

16.

Sheet stamping molding system example

SATOH's base material handling technology contributes to automation

Product Information

17.

Experimental mini hot press

Easy Installation, excellent in ease of use

Peripherals

18.

Mold changer

Helping rationalization with single step change

Peripherals

19.

Mold maintenance equipment

We design and manufacture equipment according to your needs.

Peripherals

20.

Thermoplastic composite drawing device

Molding of continuous fiber reinforced structural material is possible

Technical Information

21.

Development-acceptance of mass production prototypes

Assistance in development with a trial machine (confidentiality support)

Technical Information

22.

System engineering

Rationalization consultation, anything is available

Product Information

23.

Heat press machine

Lineup of 40t to 1800t (tabletop 5t to 20t are also available)

Peripherals

24.

Hot plate flat mold for 100t lab machine

Compatible with various sizes